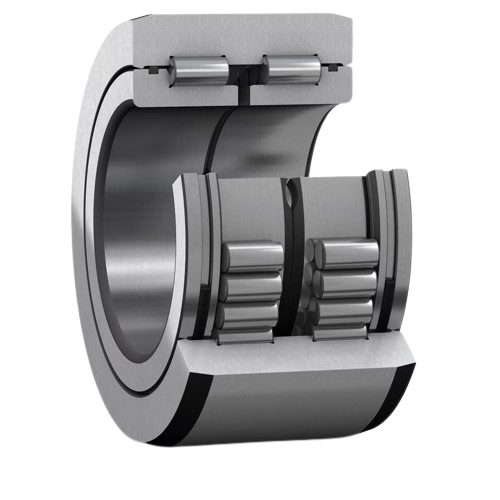

NoWear Coated Bearings

NoWear is a wear-resistant carbon coating that can be applied to the rolling elements of a bearing and the inner ring rolling paths (identification suffix L7DA) or only to the rolling elements (identification suffix L5DA).

The wear-resistant carbon coating is applied using a physical vapor deposition process. The thickness of the coating varies between 1 to 3 μm, depending on the size of the bearing. The hardness of the coating is 1,200 HV10.

NoWear-coated bearing surfaces adopt the hardness of the coating while maintaining the toughness of the underlying material, along with improved friction properties and wear resistance.

During the running-in period, only a small amount of coating material is transferred to the counter surfaces. This coating reduces friction and increases resistance to wear and contamination, even in bearings where only the rolling elements are coated.

Product details